1st, Chnage of nozzle

2nd, Change of nozzle distance

The nozzle distance must fit for the bolt length

to change the nozzle according to the length of bolt, finally the bolt length must same to jack nut length.

3rd step, after changed nozzle and length of bolt

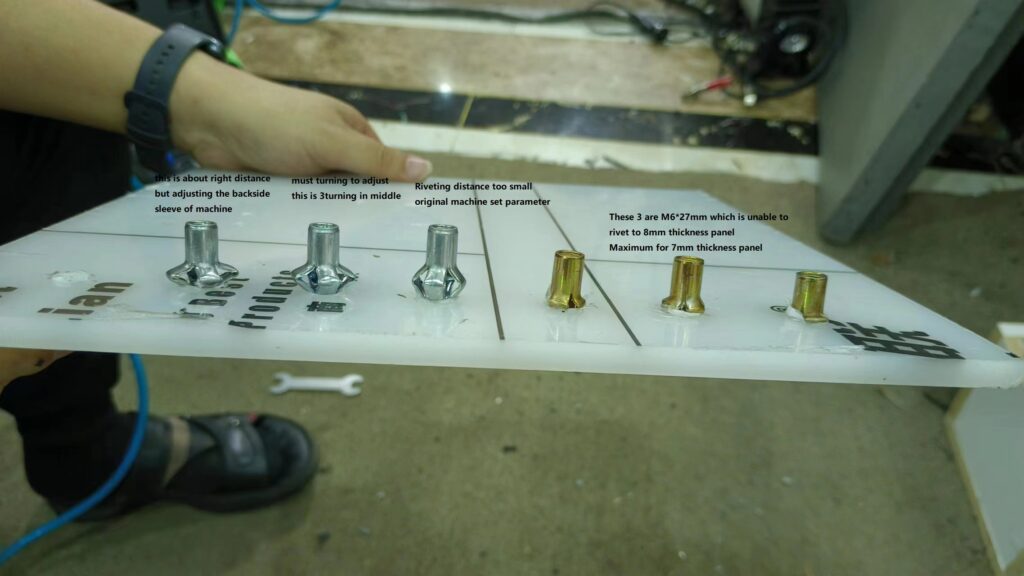

adjusting the riveting length, riveting distance is important, if too small, the riveting nut will not fit properly, the riveting strenght is low. please check below picture

Always lubricate the bolt before using to the jack nut.

then we can work with the machine

1st we tried use normal M6*27mm jack nut on 8mm panel which is unable to rivet, because M6*27mm can only be used on 0.5-7mm thickness panel, as you can see from above picture, the nut is not riveting in place. failed.

2nd we use M6*33mm flat head jack nut

As you can see, from left to right, silver color is flat head, which fit verywell from front side.

this is back side, the from left to right, 1st jack nut is the best, by adjusting the rivet length to achieve the best riveting distance.

3rd, we use M6*33 CSK head jack nut

as you can see from front side, the flat head and csk head all can hold on 10mm diameter hole in good position. second row, first two are csk head.

Below is the picture from back side. all hold very well on 8mm thickness panel for both flat head and csk head.

we can’t remove the jack nut by plier