Description

- Product Name:

ALCLAD ® ALUMINIUM COMPOSITE PANEL (ACP)

- Manufacturer: CHANGZHOU ALCO INTERNATIONAL CO.,LTD

NO.25 Longfei Road, Changzhou Jiangsu, China

- Product Description

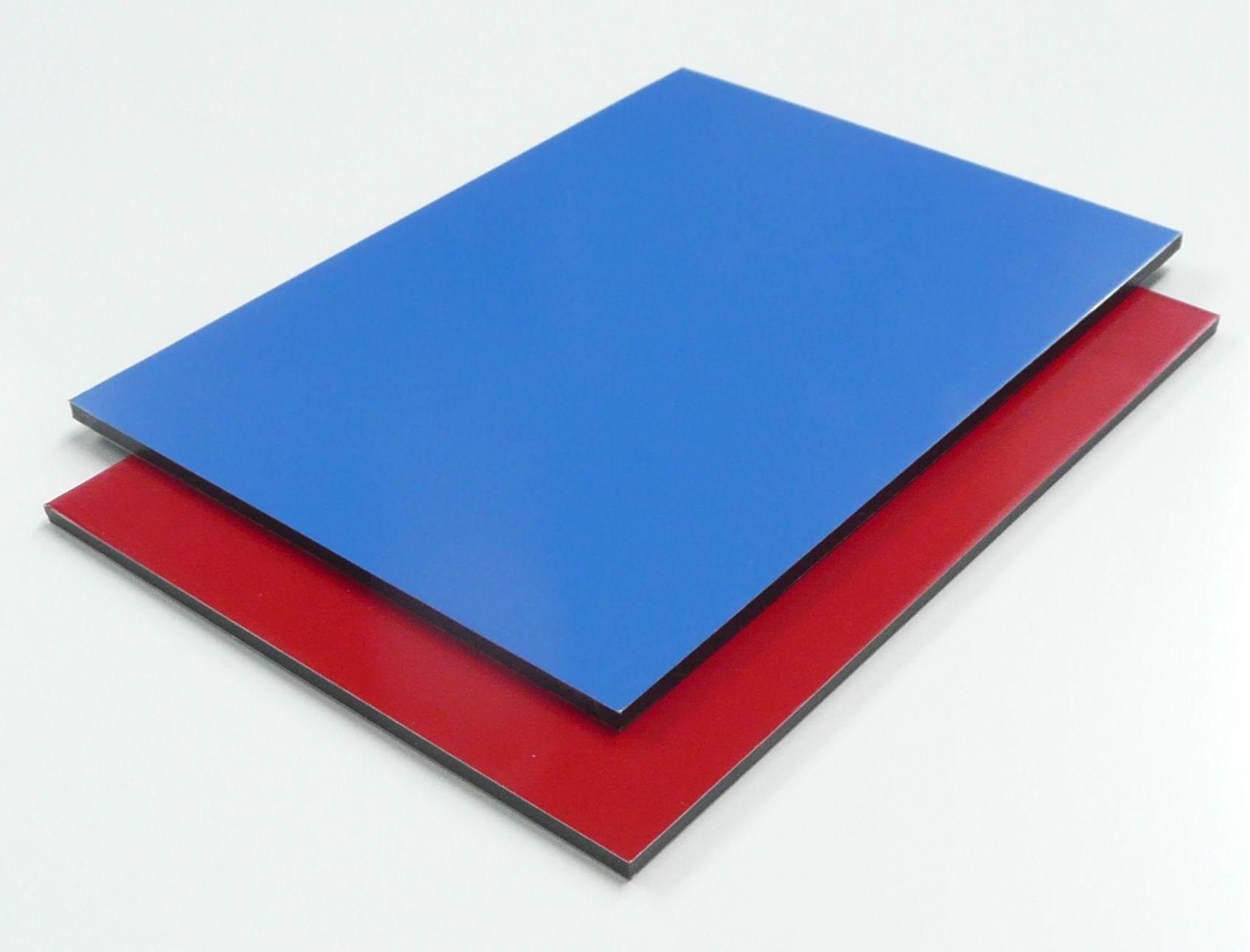

BASIC USE: ALCLAD ® ACP is a lightweight, rigid, bendable and durable aluminium faced composite panel with strong temperature ranging from -50℃ to 80℃, widely used as interior and exterior wall cladding.

COMPOSITION & MATERIALS

ALCLAD ® ACP panels consist of a core of thermoplastic material thermally bonded to aluminium sheets, DuPont Bynel® as bonding layer coextruded on the surface of plastic core, fabricated of aluminium alloy, 0.020″ (0.5 mm) thick or an equivalent.

Dupont : Bynel® 3000 Series adhesive resins

TYPES

Several types of ACP panels are available including:

- ALCLAD ® standard panels

- ALCLAD ® fire-resistant panels— FR ACP fire safty test

- ALCLAD ® Stone finish panels

- ALCLAD ® Steel composite panels—STEEL COMPOSITE PANEL (SCP)

- ALCLAD ® Anti-scratch PE panels (NEW!)

SIZES

ALCLAD® panels are available in 3, 4 and 6 mm thicknesses in standard widths of 1220mm ,1250mm and 1500mm and in standard lengths of 2440mm, 2500mm, 5000mm.

A range of custom sizes is available:

- Width : 800mm- 1500mm

- Length : 1600mm-5000mm

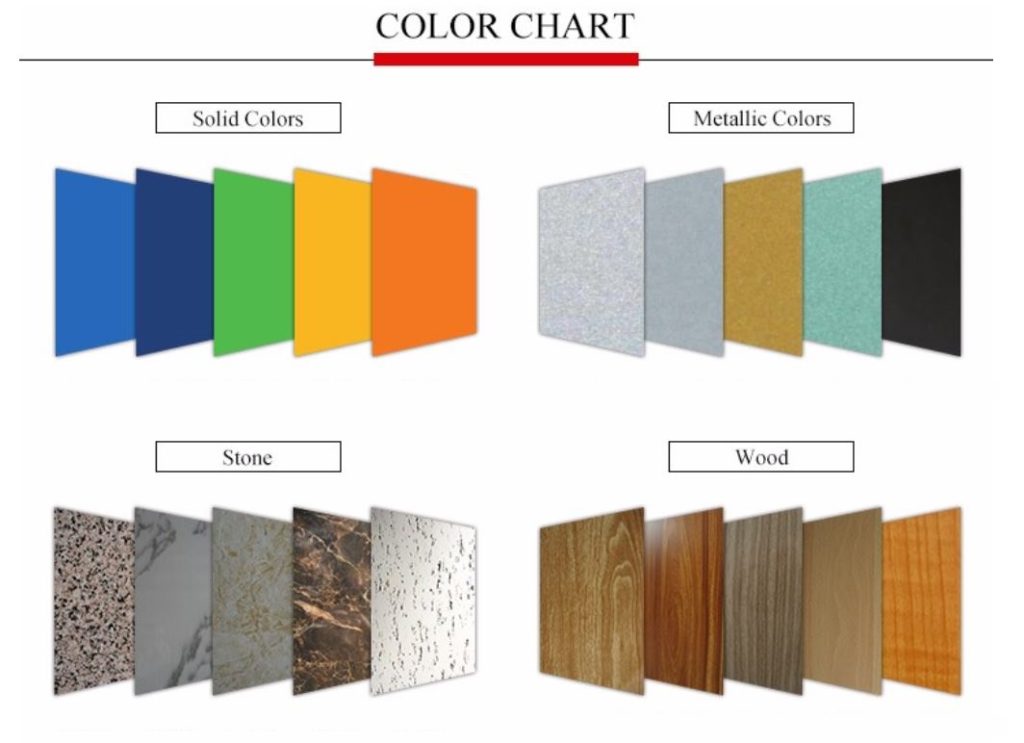

FINISHES

- PPG INDUSTRIAL COATINGS —PpG DuranarCoil

- BECKER INDUSTRIAL COATINGS

- VALSPAR INDUSTRIAL COATINGS

- FLUOROFINE NANO-TECH ANTI-DIRT SELF CLEAN COATINGS (NEW!)

Standard ALCLAD ® ACP with KYNAR 500® or HYLAR5000® Fluoropolymer (PVDF) finishes is available in wide range of colors and a broad spectrum of gloss levels, Meets or exceeds the performance requirements of AAMA 2605

Stone Series is a simulated stone fluoropolymer finish combined with fluoropolymer colors in white marble and red, pink, white and black granite finishes.

Highly durable PVDF coatings have provided long-term beautification of metal building panels and components for near 40 years.

Ginna Nuclear Power Station, built in 1967, used PVDF coating and keep integrity of the coating for near 40 years.

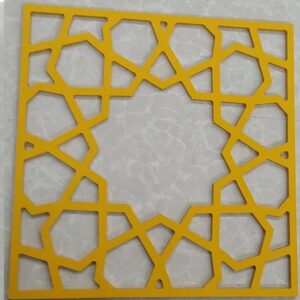

SHAPES & FABRICATION

ALCLAD® panels can be cut, routed and formed with conventional woodworking tools. Angle bends are formed by routing the back of the panel prior to shaping. The common pan shape is formed by routing the back edges, trimming the corners and bending and reinforcing the edges.

ALCLAD® can be rolled on a pyramid or 4-stand roll bender to a curved shape for curved corners or column covers. Bumping on a press brake also can be used to produce a curved surface.

Details please refer to our Material Processing Manual: ACP Material Processing Manual

- Technical Data

APPLICABLE STANDARDS

- ASTM: American Society for Testing and Materials.

- DIN: German Industrial Standard.

- NFTC: National Center For Quality Supervision and Testing of Fire Building Materials

- CBMTC: National Research Centre of Testing Techniques for Building Materials

Details please refer to our Mechanical and Physical property. ACP Technical Data

ALCLAD ® fire-resistant panels (FRACP)

Total Thickness: 4mm (nominal)

Aluminium thickness of both sides: 0.5mm

Panel Weight: 1.58 (lb./sq. ft.) or 7.7(kg/sq.m.)

German DIN4102-1998 Class B1:

- Minimum residual length -Pass

- Average residual length -Pass

- Average effluent temperature -Pass

- Flame height -Pass

Tested by SGS world wide. Certificate can be acquired at your request.

- Installation

PREPARATORY WORK

The manufacturer recommends field measurement prior to fabrication. Verify alignment of surfaces to receive panels.

Wind calculation: WindLoadCalculations for ACP

APPLICATION

ALCLAD® surfaces can be attached to one another or to other materials by conventional methods of attachment – rivets, bolts or screws. For interior installation, flat surfaces of ALCLAD® can be attached to substrates such as gypsum board using double-faced tape or non-hardening adhesive.

Our factory picture

- Characteristics:

| 4MM ACP PHYSICAL PROPERTIES | ||||

| Properties | Standard | Test value | Result | |

| Aluminium thickness, in (mm) | 0.5 | 0.5 | PASS | |

| Weight, in (lb./sq. ft. | kg/sq. m.) | 1.13 lb./sq. ft. | 5.5 kg/sq. m. | |||

| Coefficient of linear thermal expansion, (μm/m/°C) | ASTM D696-2003 | 218.5 | PASS | |

| Thermal deformation temperature (℃) | ASTM D648-2007 | 95.2 | PASS | |

| Flexural rigidity (MPa) | ASTM D790-2003 | 109 | PASS | |

| Flexural elasticity (MPa) | ASTM D790-2003 | 12480 | PASS | |

| Impact resistance (MPa) | ASTM D732-2002 | 27.4 | PASS | |

| Adhesive strength (kg/mm) | ASTM D903-98(2004) | 97 | PASS | |

| Adhesion (B) | ASTM D3359-2002 | 5 | PASS | |

| Mandrel bend test (T) | ASTM D522-93a(2001) | 1 | PASS | |

| Pencil hardness | ASTM D3363-2000 | 3H | PASS | |

Contact our sales department for price, or through our agents.

- Packing Terms.

Fully loading packing in one 20’ container:

1200 pcs of 4mm ACP, size of 1220mm by 2440mm.

(500pcs/case ×2cases, 50pcs/case×4cases)

1700 pcs of 3mm ACP, size of 1220mm by 2440mm.

(640pcs/case ×2cases, 105pcs/case×4cases)

Only can be Unloaded pcs by pcs artificially

Otherwise please contact sales department for more details.

- Delivery Time:

The date of the delivery is depend on your order quantity,usually at 21days. please contact our sales department for details.

- Warranty

We guarantee when correctly mounted and properly operated and maintained, shall give satisfactory performance for a period of 20 years counting from the date on which the commodity delivered from the company.

Details please refer to our Certificate of Quality Guarantee

- Maintenance

PVDF is a long-term, maintenance-free finish. Under normal exposure and use, it is self-cleaning through rain washing. Water flush or power washing with a mild deter-gent is recommended to remove heavy soil.

- Technical Services

Contact ALCLAD® for technical assistance with design and specification or for the name of a nearby representative.

Indonesia Petrolic station

|

|

![]() DUPONT AUTHORIZED CERTIFICATE INSURING

DUPONT AUTHORIZED CERTIFICATE INSURING

IT’S BEST BONDING QUALITY.

PPG DURANAR® / DURACRON® COATINGS GIVE

PPG DURANAR® / DURACRON® COATINGS GIVE

YOU FULL REASSURANCE OF ITS FINISH QUALITY

DURABLE COLOR FOR A WORLD ON THE MOVE — by Beckers

DURABLE COLOR FOR A WORLD ON THE MOVE — by Beckers

PAINT AND COLOR

PAINT AND COLOR

Reviews

There are no reviews yet.